Blog

Filter categoryHow to achieve waterproof prints for architecture and engineering using a plotter printer

Technical Printing

|6 Dec 2024

Why Waterproof Prints Are Essential for Architecture and Engineering

Standard prints often aren't enough in the architecture and engineering fields. These industries demand waterproof prints and documents that are resilient to challenging environments, keeping their clarity and durability even in the toughest of locations.

Challenges of Outdoor and On-Site Printing

Printed materials face several challenges on construction sites and in field operations. Rain, humidity, and direct sunlight are some environmental challenges. Frequent handling by multiple team members adds further strain to prints. These harsh conditions can smudge drawings, fade specifications, and lead to costly mistakes or delays.

Advantages of Waterproof Prints for Professionals

Waterproof prints guard against these damages, providing peace of mind for architecture and engineering professionals. When exposed to moisture, these prints retain their integrity. Critical measurements, annotations, and details stay legible throughout the entire project, leading to fewer reprints, reduced costs, and improved team efficiency.

How HP Plotters Support Durable, Weather-Resistant Prints

HP plotters are specifically designed to produce weather-resistant prints. They use advanced technology and precision engineering to ensure a perfect print, even in imperfect conditions. By using specialised inks and media-handling capabilities, HP plotters can produce high-resolution prints that consistently convey the information needed in areas where moisture would otherwise ruin a print.

Choosing the Right Ink for Waterproof Printing

Is Pigment Ink Waterproof?

Due to its molecular structure, pigment ink is inherently water-resistant. While dye-based inks dissolve in their carrier liquid, pigment inks are made of solid particles suspended in a liquid medium. As they dry on a printing surface, they create a durable, water-resistant layer that adheres strongly to the media.

Benefits of Pigment Ink for Long-Lasting Prints

Compared to traditional inks, pigment inks have better fade resistance, improved water resistance, and superior UV stability. These are just the properties the architectural and engineering fields need to maintain clarity and accuracy in their drawings. They greatly improve the print's resilience to challenging environmental conditions.

Comparing Pigment Ink to Dye-Based Ink for Durability

Dye-based inks are undoubtedly great for providing vibrant colours to prints. But what they have in flashiness, they lose in practicality, at least for the challenging conditions in the architectural and engineering fields. The lack of resiliency that dye-based inks have to exposure to water and light (and their reduced longevity) doesn't compare to pigment ink for serious professionals.

Selecting Waterproof Media for Plotter Printing

Recommended Waterproof Media Types

Several types of media can be used for waterproof printing, including synthetic papers, polyester films, and specially coated papers. Each option differs in its benefits, offering unique tradeoffs between durability, print quality, and affordability. The choice should align with the project's requirements and the conditions in which it will be used.

Handling and Storage Tips for Waterproof Media

Being more durable doesn't mean being invincible. So, to get the most out of waterproof prints, the media should be stored in a controlled environment to prevent physical damage. Careful handling of the media during loading and unloading also helps prevent surface contamination that may weaken the waterproofing of the media.

Ensuring Media Compatibility With Your Plotter

Not every type of waterproof media is compatible with every plotter model. When choosing a material for a print job, it's important to verify that it will work with the plotter that will be used to print on it. Characteristics like media thickness, coating compatibility, and environmental requirements should be considered.

Setting Up Your Plotter for Waterproof Prints

Optimising Print Quality for High-Resolution Waterproof Output

In addition to selecting the right media, setting up the plotter correctly for the media is a requirement for getting good results. This includes selecting appropriate resolution settings, colour management profiles, and print modes. The choices should balance quality with production speed, according to the project's needs. Regular calibration of the plotter will ensure that prints using the same settings remain consistent across multiple jobs.

Adjusting Plotter Settings for Ink Adhesion

Getting the best quality out of an initial print is one thing, and ensuring that quality is good under difficult conditions is another. Settings such as drying time, heating temperature, and ink density should be set to match the specific media being used and the environmental conditions the print will need to withstand. Getting these correct will improve the longevity of the print.

Using Test Prints to Verify Waterproof Quality

Before printing something critical to a project's success, it's a good idea to do a test print to gauge how the various settings and media impact water resistance. This allows for identifying potential issues early in the process so they don't occur after a large print job or during an important job.

HP Plotter Features That Support Waterproof Printing

High-Precision Print Modes for Clarity and Detail

HP plotters have various high-precision print modes that optimise output quality while creating waterproof prints. These modes are designed to ensure accurate line reproductions, consistent colour density, and sharp text, even in the most challenging environmental conditions.

Advanced Ink Management for Consistent Results

Both the quality and durability of a print depend greatly on proper, even ink coverage. HP plotters use advanced ink management systems to control ink delivery. These systems maintain print quality while maximising ink efficiency.

HP PrintOS for Monitoring and Managing Waterproof Print Jobs

The HP PrintOS platform provides tools for monitoring and managing print jobs to achieve consistent quality across multiple projects. This system helps track media usage, maintain printer health, and optimise workflow efficiency.

Best Practices for Maintaining Waterproof Prints

Protecting Prints from Fading and Smudging

Like the media itself, final prints must be handled with care to ensure the best longevity. Proper handling and storage include:

- Avoiding excessive touching of the print

- Keeping it out of direct sunlight as much as possible

- Storing it in appropriate containers when not in use

Proper Storage and Handling of Waterproof Prints

Proper storage for a waterproof print consists of a clean, dry environment away from direct sunlight and extreme temperatures. By keeping the prints out of harsh conditions as much as possible, they'll last longer when exposed to them.

Field Tips for Maintaining Print Quality On-Site

On-site handling also requires special attention to maintain print quality. This includes using protective covers while moving the prints, avoiding prolonged exposure to extreme conditions, and implementing proper storage solutions for downtime at job sites.

Achieving Durable, Waterproof Prints for Demanding Projects

Successfully creating waterproof prints requires a comprehensive approach. The right technology must merge with the appropriate materials, and your team must follow best practices. By following the guidelines above and leveraging the power of HP plotters like the HP DesignJet, architecture and engineering professionals can achieve durable, high-quality prints that meet the demands of their jobs.

You Might Also Like

Plotter Printers

Plotter PrintersWhy using HP MFP for scanning helps reduce rework

- HP DesignJet

Cost-effective printing of safety plans and wayfinding information

- Sustainability

Paper-saving techniques when printing AEC blueprints

- How-To

How to nake your printer faster for urgent blueprints

- Plotter Printers

Plotter care habits that keep your blueprints job-ready

- Digital Tools

Remote printing guide to increase AEC workflow efficiency

- Plotter Printers

Cut AEC operating costs with HP Plotters

- Sustainability

How scheduling plotter saves electricity costs

- Digital Tools

How HP Click can streamline working processes

6 tips to portfolio printing for AEC professionals

HP DesignJet

HP DesignJetBlueprint annotation guide: How to add notes that stay sharp on paper

GIS

GISPrinting topographical maps: What AEC professionals should know

How-To

How-ToA guide to large format printing for architects and designers

GIS

GISHow GIS mapping tools support large format printing for civil engineering

How-To

How-ToHow to use large format plotters for facility management floorplans

CAD Printing

CAD PrintingCommon print file types for blueprints explained

How-To

How-ToCommon mistakes and fixes for poor-quality blueprints

How-To

How-ToCommon printing mistakes: How to avoid costly errors in large format jobs

How-To

How-ToDigital vs paper: When to print architectural drawings and when to share digitally

How-To

How-ToBest practices for marking up and revising printed architectural plans

Related printers

HP DesignJet T850 36-in Multifunction Printer + HP Installation Service for DesignJet Series Entry Level (APJ)

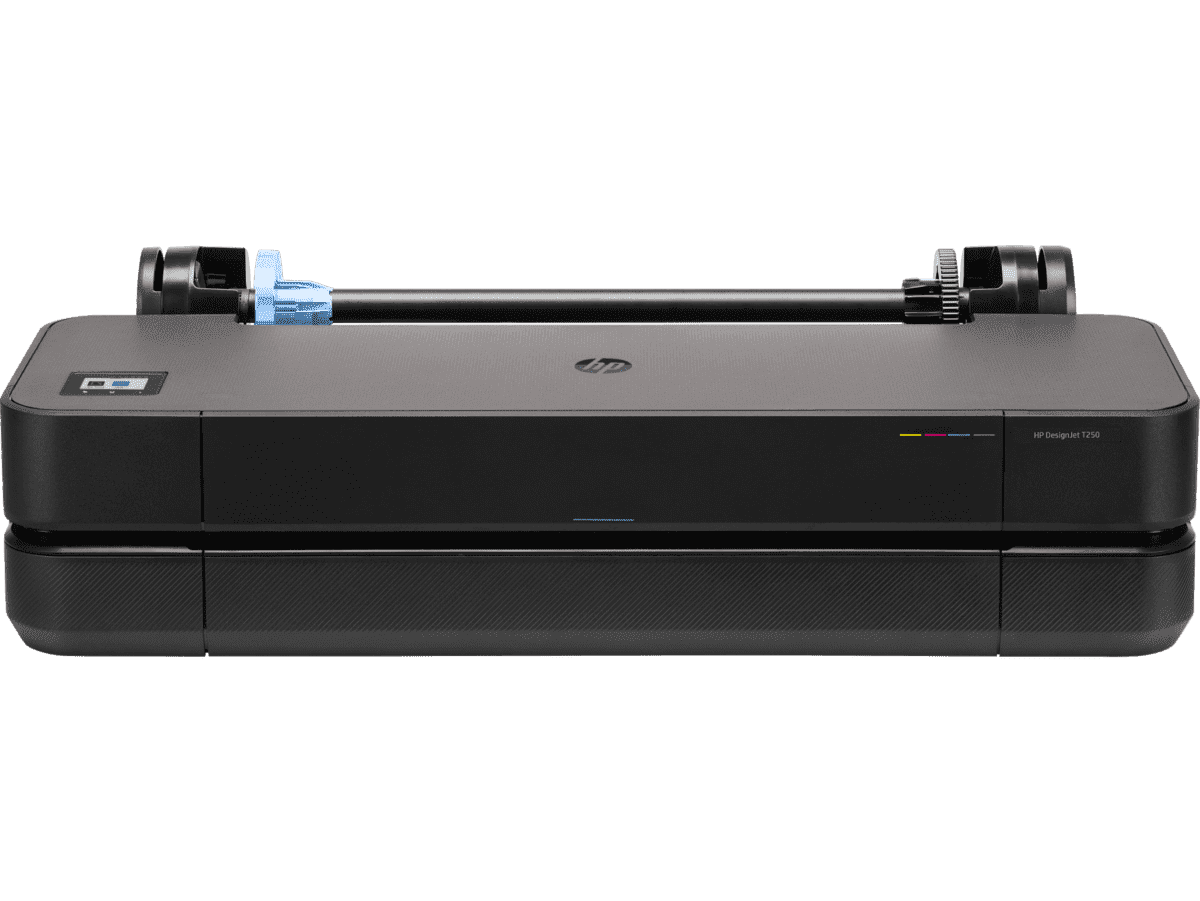

HP DesignJet T250 24-inch Compact Large Format A1 Plotter Printer + HP DesignJet T200/T600 Automatic Sheet Feeder + HP Installation Service for Design

HP DesignJet T650 24-in Printer + HP Installation Service for DesignJet Series Entry Level (APJ)

HP DesignJet T650 36-in Printer + HP Installation Service for DesignJet Series Entry Level (APJ)