Blog

Filter categoryHow to troubleshoot plotter paper jams

Technical Printing

|15 Oct 2024

Professionals in industries relying on large format printing have come to depend on the reliability of their printers. An unexpected paper jam in a printer plotter wastes time and can lead to costly damage to the plotter when not addressed properly. In this guide, we'll explore the common reasons for a plotter jam and provide step-by-step solutions.

Common Causes of Plotter Paper Jams

If you're going to address a paper jam in a printer plotter properly, you first need to know what causes them. Two primary issues contribute to the majority of plotter jams:

Incorrect Paper Size or Type

Worn Out Rollers or Print Heads

Step-by-Step Guide to Fix Plotter Jams

Any paper jam in a printer plotter should be addressed promptly to keep your plotter from becoming damaged. Follow the steps below to fix plotter paper jams:

Safely Removing Paper Jams Without Damaging the Plotter

Inspecting for Any Remaining Obstructions

Resetting the Plotter After Clearing a Jam

Preventing Future Plotter Paper Jams

Ideally, you'll prevent a paper jam in a printer plotter from ever occurring rather than having to deal with them when they do. The best practices below will help minimise the chances of a jam:

Properly Loading Paper Into the Plotter

Regular Maintenance to Avoid Paper Jam Issues

Using the Correct Paper Type and Quality

How HP Plotters Help Reduce Paper Jams

Advanced Features for Jam Prevention

Efficient Paper Handling and Automatic Alignment

Keep Your Plotter Running Smoothly by Troubleshooting and Preventing Jams

Armed with the knowledge of how plotter paper jams occur and how to address them when they do, you'll be able to reduce downtime and significantly extend your plotter's life. To get even more life out of your investment, consider taking advantage of the advanced features offered by the HP DesignJet line.

Explore plotter printers for your needs

HP DesignJet T850 36-in Multifunction Printer + HP Installation Service for DesignJet Series Entry Level (APJ)

A0 Color HP DesignJet Large Format Printer, Perfect for Business Print, copy, scan Dynamic security enabled printer 25 sec/page on A1 Ethernet, Wi-Fi Touchscreen, Automatic document feeder, Front USB flash drive port, Scan to PDF

MYR 18365.00MYR 17480.00Buy now

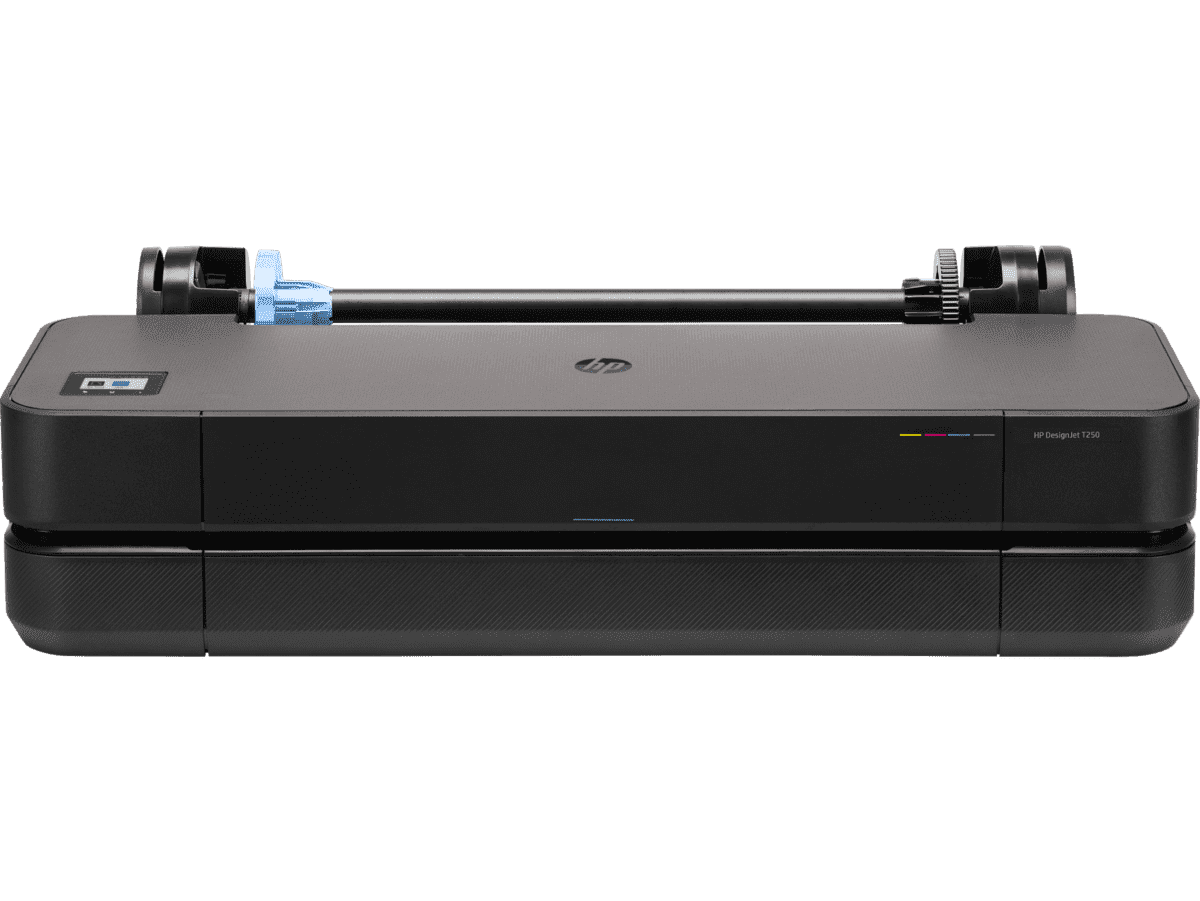

HP DesignJet T250 24-inch Compact Large Format A1 Plotter Printer + HP DesignJet T200/T600 Automatic Sheet Feeder + HP Installation Service for Design

A1 Colour HP DesignJet Large Format Printer, Perfect for Small Offices & Business Print 30 sec/page on A1; 76 A1 prints per hour USB, Ethernet, Wi-Fi Touchscreen; Automatic document feeder; Front USB flash drive port

MYR 5860.00MYR 4980.00Buy now

HP DesignJet T650 24-in Printer + HP Installation Service for DesignJet Series Entry Level (APJ)

Functions: PrintAuto sheet feeder: A4, A3; manual feed: A4, A3, A2, A1Print quality color: Up to 2400 x 1200 optimized dpiPrint speed: 26 sec/page on A1, 81 A1 prints per hour[1]Number of print cartridges: 4 (C, M, Y, K)

MYR 8570.00MYR 6880.00Buy now

HP DesignJet T650 36-in Printer + HP Installation Service for DesignJet Series Entry Level (APJ)

Functions: PrintAuto sheet feeder: A4, A3; manual feed: A4, A3, A2, A1, A0Print quality color: Up to 2400 x 1200 optimized dpiPrint speed: 25 sec/page on A1, 82 A1 prints per hour[1]Number of print cartridges: 4 (C, M, Y, K)

MYR 11640.00MYR 9880.00Buy now

You may also like

Plotter Printers

Plotter PrintersReducing High-Volume Printing Costs in Malaysian AEC

Plotter Printers

Plotter PrintersWhy using HP MFP for scanning helps reduce rework

- HP DesignJet

Cost-effective printing of safety plans and wayfinding information

- Sustainability

Paper-saving techniques when printing AEC blueprints

- Plotter Printers

Plotter care habits that keep your blueprints job-ready

- How-To

How to nake your printer faster for urgent blueprints

- Digital Tools

Remote printing guide to increase AEC workflow efficiency

- Plotter Printers

Cut AEC operating costs with HP Plotters

- Sustainability

How scheduling plotter saves electricity costs

6 tips to portfolio printing for AEC professionals

- Digital Tools

How HP Click can streamline working processes

HP DesignJet

HP DesignJetBlueprint annotation guide: How to add notes that stay sharp on paper

GIS

GISPrinting topographical maps: What AEC professionals should know

How-To

How-ToA guide to large format printing for architects and designers

GIS

GISHow GIS mapping tools support large format printing for civil engineering

How-To

How-ToHow to use large format plotters for facility management floorplans

How-To

How-ToCommon mistakes and fixes for poor-quality blueprints

CAD Printing

CAD PrintingCommon print file types for blueprints explained

How-To

How-ToCommon printing mistakes: How to avoid costly errors in large format jobs

How-To

How-ToDigital vs paper: When to print architectural drawings and when to share digitally

Select Your Country/Region and Language

Close Country/Region Selector Dialog- Africa

- Afrique

- België

- Belgique

- Česká republika

- Danmark

- Deutschland

- Eesti

- España

- France

- Hrvatska

- Ireland

- Italia

- Latvija

- Lietuva

- Magyarország

- Middle East

- Nederland

- Nigeria

- Norge

- Österreich

- Polska

- Portugal

- România

- Saudi Arabia

- Slovenija

- Slovensko

- South Africa

- Suisse

- Suomi

- Sverige

- Switzerland

- Türkiye

- United Kingdom

- Ελλάδα

- България

- Казахстан

- Србија

- Україна

- ישראל

- الشرق الأوسط

- المملكة العربية السعودية

HP Worldwide

Select Your Country/Region and Language

- Africa

- Afrique

- América Central

- Argentina

- Asia Pacific

- Australia

- Bangladesh

- België

- Belgique

- Bolivia

- Brasil

- Canada

- Canada - Français

- Caribbean

- Česká republika

- Chile

- Colombia

- Danmark

- Deutschland

- Ecuador

- Eesti

- España

- France

- Hong Kong SAR

- Hrvatska

- India

- Indonesia

- Ireland

- Italia

- Latvija

- Lietuva

- Magyarország

- Malaysia

- México

- Middle East

- Nederland

- New Zealand

- Nigeria

- Norge

- Österreich

- Pakistan

- Paraguay

- Perú

- Philippines

- Polska

- Portugal

- Puerto Rico

- România

- Saudi Arabia

- Singapore

- Slovenija

- Slovensko

- South Africa

- Sri Lanka

- Suisse

- Suomi

- Sverige

- Switzerland

- Türkiye

- United Kingdom

- United States

- Uruguay

- Venezuela

- Việt Nam

- Ελλάδα

- България

- Казахстан

- Србија

- Україна

- ישראל

- الشرق الأوسط

- المملكة العربية السعودية

- ไทย

- 中华人民共和国

- 臺灣 地區

- 日本

- 香港特別行政區

- 한국

- Recalls |

- Product recycling |

- Accessibility |

- Privacy |

- Terms of use |

- Limited warranty statement |

- Use of Cookies |

©2026 HP Development Company, L.P. The information contained herein is subject to change without notice.