Blog

Filter categoryHow scheduling plotter saves electricity costs

Technical Printing

|20 Nov 2025

Electricity costs have been rising in Malaysia, placing a financial burden on businesses and households alike. As costs continue to climb, finding ways to reduce energy becomes more important. One overlooked way for businesses to do this is to schedule plotter usage in more intelligent ways. Plotters are essential tools across many industries, but they consume a large amount of electricity. The problem gets worse when the machine is used inefficiently. This article explains how to save electricity costs through strategic plotter scheduling.

Understanding the Impact of Rising Electricity Bills

Current Trends in Electricity Prices in Malaysia

The tariff structure in Malaysia has changed quite a bit in recent years, resulting in steady increases in monthly bills for consumers. Many residential and commercial users have found their bills rising after the implementation of the Imbalance Cost Pass-Through mechanism. Industrial and commercial sectors have been particularly impacted, with the main culprit being energy-intensive equipment like plotters.

Factors Contributing to the Rise in Electricity Costs

The global economy has played a big role in cost increases in Malaysia. The worldwide demand for fossil fuels has driven prices upward. Meanwhile, the country's ongoing transition to cleaner energy sources requires significant investment in infrastructure. Currency fluctuations affecting fuel imports, maintenance costs for ageing power plants, and the phasing out of electricity subsidies have all contributed to higher tariffs. On top of these factors, Malaysians are using more energy, placing greater demand on the system and further driving up costs.

The Financial Burden on Businesses and Households

The rising costs of electricity are straining every sector of Malaysian society. Businesses that rely heavily on plotters and other electrical equipment are, predictably, among the hardest hit. Households are finding that their electricity bills are taking up a larger portion of their monthly budgets. In response to this burden, many Malaysians are looking for ways to reduce energy consumption without also reducing their productivity or quality of life.

The Benefits of Scheduling Plotters

What Plotter Scheduling Is and How It Works

Large format printing tasks use a lot of energy, but deciding to schedule plotter operations efficiently can minimise that usage, creating savings that can add up to significant amounts. This process involves several approaches:

- Batching print jobs during off-peak hours when electricity rates are lower

- Setting up automatic power-down modes during idle periods

- Coordinating print scheduling cycles across multiple departments to reduce redundancy

A good modern plotter, such as the HP DesignJet series, will have features built in to make all of these scheduling tasks easy to set up.

Key Benefits: Energy Savings and Increased Efficiency

A more strategic schedule plotter approach offers several advantages beyond cost reduction alone:

- Improved operational efficiency from reduced warm-up cycles

- Easily scheduled maintenance to improve plotter lifespan

- Improved employee productivity from more predictable printing workflows

In each of these areas, printing each document as needed introduces bottlenecks that are removed when documents are batched together to be printed all at once.

Cost Savings Analysis

Potential Cost Savings From Scheduling Plotters

Depending on the volume of printing a business relies on, the cost savings of deciding to schedule plotter operations can be quite large. A typical large format plotter needs around 50 to 200 watts while actively printing and five to 30 watts in sleep mode. Some models even draw power when ostensibly turned off.

Businesses that schedule print operations to run during the less expensive hours and ensure plotters are in deep sleep mode while not in use can find their plotter-related energy consumption reduced by 30 to 50 per cent. AEC firms running multiple plotters throughout the week may find themselves saving hundreds or even thousands of ringgit annually.

Energy Consumption Before and After Scheduling

Comparative analysis reveals dramatic differences in energy consumption patterns between scheduled and unscheduled plotter operations. Businesses that have no scheduling practice in place often leave plotters in ready mode for the entirety of the business day. This draws power during extended periods of non-use. If a plotter consumes 100 watts in standby mode, it's taking up 800 watt-hours of electricity while providing no benefit to the business.

After implementing a scheduling protocol, that same machine might be active for only three hours daily, staying in deep sleep mode for the remaining five hours. This reduces the idle energy consumption from 800 watt-hours to 375 watt-hours, a 53% reduction in energy usage. But when you schedule plotter tasks, you gain more than short-term wins.

Long-Term Financial Benefits and Return on Investment

Direct energy savings are an important benefit, but there are also long-term financial advantages that compound over time. When plotters have fewer operating hours, they also have reduced wear on mechanical components. This increases equipment lifespan and delays the need for costly replacements. Businesses that can reduce their energy consumption below a certain threshold may also be eligible for green building certifications or sustainability initiatives offered by the Malaysian government.

These long-term savings mean that the initial expense of a good plotter is spread out over a longer period of time than one that needs to be replaced due to poor operational efficiency, increasing the return on investment that businesses see from their purchase.

Additional Energy-Saving Measures for Plotter Usage

Complementary Strategies to Plotter Scheduling

Of course, plotter scheduling alone will not solve all of a business's plotter-related energy woes. There are other actions that can be taken to further reduce energy consumption in these devices:

- Perform maintenance regularly to keep plotters working at peak efficiency.

- Upgrade to energy-efficient models with better sleep modes and faster printing.

- Use print management software to eliminate unnecessary jobs and make scheduling a printer simpler.

- Create policies to discourage frivolous printing and encourage digital proofing.

Further Reducing Electricity Costs

There are actions that can be taken outside of the plotter itself as well:

- Install energy-efficient LED lighting in printing areas.

- Ensure proper ventilation to prevent excess heat that impacts machine performance.

- Train staff on energy-conscious practices to schedule plotter use more effectively.

- Consider renewable energy options such as solar panels.

Start Saving on Electricity Costs With HP

HP realises the importance of energy efficiency in their product design, which is why our DesignJet models feature advanced scheduling capabilities, ENERGY STAR certification, and intelligent sleep modes. These features combine to dramatically reduce power consumption, allowing Malaysian businesses to realise significant energy savings while retaining the high-quality prints that the AEC industry demands. To get your own HP plotter and begin saving money, take advantage of our DesignJet promo.

Explore plotter printers for your needs

HP DesignJet T850 36-in Multifunction Printer + HP Installation Service for DesignJet Series Entry Level (APJ)

A0 Color HP DesignJet Large Format Printer, Perfect for Business Print, copy, scan Dynamic security enabled printer 25 sec/page on A1 Ethernet, Wi-Fi Touchscreen, Automatic document feeder, Front USB flash drive port, Scan to PDF

MYR 18365.00MYR 17480.00Buy now

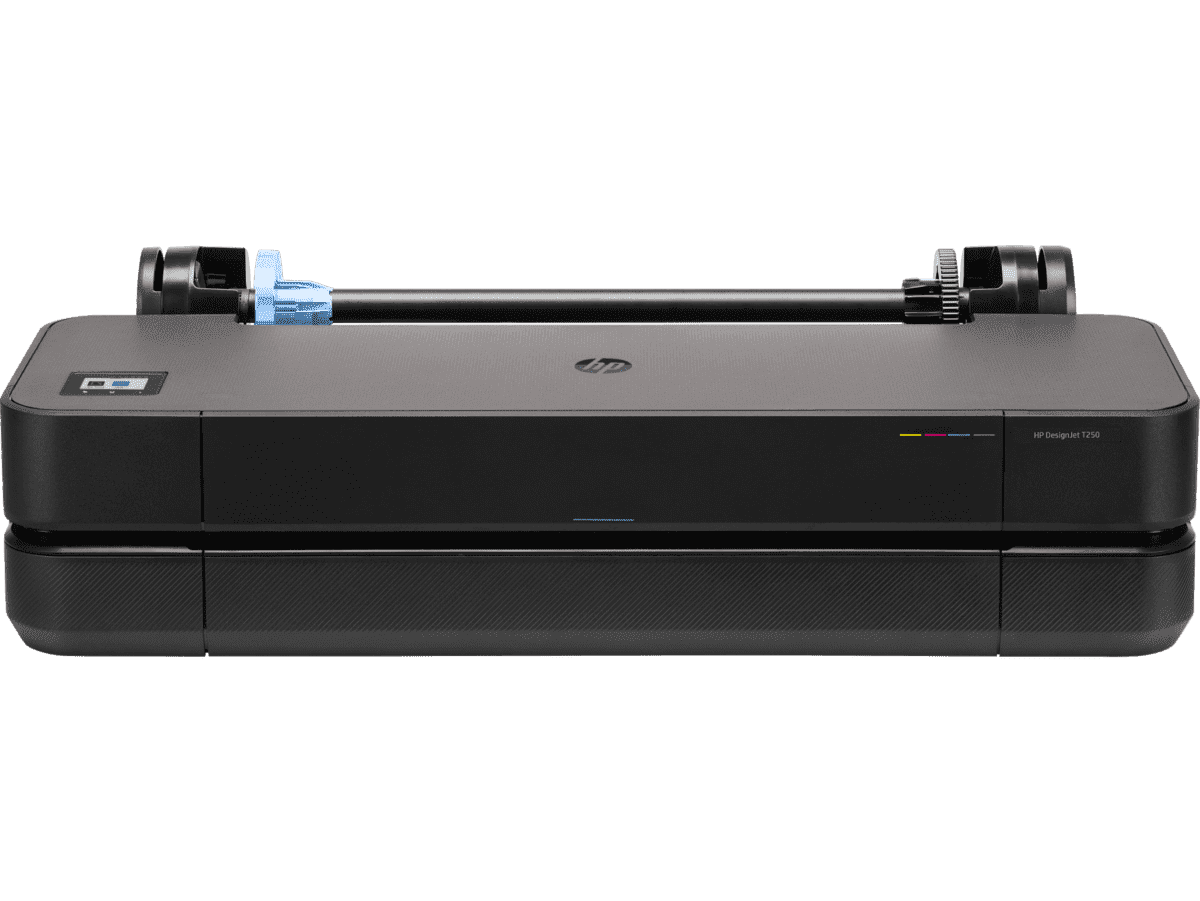

HP DesignJet T250 24-inch Compact Large Format A1 Plotter Printer + HP DesignJet T200/T600 Automatic Sheet Feeder + HP Installation Service for Design

A1 Colour HP DesignJet Large Format Printer, Perfect for Small Offices & Business Print 30 sec/page on A1; 76 A1 prints per hour USB, Ethernet, Wi-Fi Touchscreen; Automatic document feeder; Front USB flash drive port

MYR 5860.00MYR 4980.00Buy now

HP DesignJet T650 24-in Printer + HP Installation Service for DesignJet Series Entry Level (APJ)

Functions: PrintAuto sheet feeder: A4, A3; manual feed: A4, A3, A2, A1Print quality color: Up to 2400 x 1200 optimized dpiPrint speed: 26 sec/page on A1, 81 A1 prints per hour[1]Number of print cartridges: 4 (C, M, Y, K)

MYR 8570.00MYR 6880.00Buy now

HP DesignJet T650 36-in Printer + HP Installation Service for DesignJet Series Entry Level (APJ)

Functions: PrintAuto sheet feeder: A4, A3; manual feed: A4, A3, A2, A1, A0Print quality color: Up to 2400 x 1200 optimized dpiPrint speed: 25 sec/page on A1, 82 A1 prints per hour[1]Number of print cartridges: 4 (C, M, Y, K)

MYR 11640.00MYR 9880.00Buy now

You may also like

Plotter Printers

Plotter PrintersReducing High-Volume Printing Costs in Malaysian AEC

Plotter Printers

Plotter PrintersWhy using HP MFP for scanning helps reduce rework

- HP DesignJet

Cost-effective printing of safety plans and wayfinding information

- Sustainability

Paper-saving techniques when printing AEC blueprints

- Plotter Printers

Plotter care habits that keep your blueprints job-ready

- How-To

How to nake your printer faster for urgent blueprints

- Digital Tools

Remote printing guide to increase AEC workflow efficiency

- Plotter Printers

Cut AEC operating costs with HP Plotters

- Digital Tools

How HP Click can streamline working processes

6 tips to portfolio printing for AEC professionals

HP DesignJet

HP DesignJetBlueprint annotation guide: How to add notes that stay sharp on paper

How-To

How-ToA guide to large format printing for architects and designers

GIS

GISPrinting topographical maps: What AEC professionals should know

GIS

GISHow GIS mapping tools support large format printing for civil engineering

How-To

How-ToHow to use large format plotters for facility management floorplans

CAD Printing

CAD PrintingCommon print file types for blueprints explained

How-To

How-ToCommon mistakes and fixes for poor-quality blueprints

How-To

How-ToCommon printing mistakes: How to avoid costly errors in large format jobs

How-To

How-ToDigital vs paper: When to print architectural drawings and when to share digitally

How-To

How-ToBest practices for marking up and revising printed architectural plans