Blog

Filter categoryPaper-saving techniques when printing AEC blueprints

Technical Printing

|5 Jan 2026

From coordination drawings to urgent site revisions, AEC teams in Malaysia frequently need to use their printers. The problem is that blueprint waste adds up quickly: misprints, incorrect scaling, unused white space, or unclear linework all require sheets to be reprinted and paper usage to be higher than it otherwise would be. Reducing this waste lowers operating costs and keeps project workflows running smoothly. This article shares practical and easy-to-adopt paper-saving techniques when printing AEC documents. We'll also explore how modern HP DesignJet plotters use nesting, print previews, and accurate first-time output to help reduce blueprint waste.

Why Reducing Blueprint Waste Matters for AEC Teams

Blueprint waste is a hidden cost that many in the AEC industry underestimate until they actually calculate their expenditure. There are two major benefits to identifying and reducing waste so you can implement paper-saving techniques when printing.

Cutting Costs Without Sacrificing Print Quality

Paper costs add up quickly across large projects. Dozens of full-size sheets might be required for a single tender submission. When that's multiplied across several active bids and ongoing construction documentation, monthly expenses can reach thousands of ringgit. On top of that, overtime for documentation staff, courier fees for urgent delivery, and other related expenses increase costs. Reducing this by even 20% can be a meaningful budget relief without any compromise in clarity or professionalism.

Minimising Delays Caused by Avoidable Reprints

Reprints waste paper, but they also waste time. When a contractor discovers a scaling error on site or when coordination drawings are outdated, the entire workflow stalls while corrected sheets are prepared and delivered. This creates a ripple effect. It leaves crews sitting idle while they wait, and other trades fall behind schedule as a result.

Practical Ways to Save Paper When Printing Blueprints

The first step to finding the right paper-saving techniques when printing is to take a close look at how AEC teams actually use printed documents. Once usage patterns are known, it's easier to develop strategies to help reduce paper waste.

Using Scalable Layouts That Reduce Empty Space

It's common for traditional blueprint layouts to contain substantial unused space. Oversized title blocks, excessive margins, and poor sheet composition can all waste space on a page. They may even require larger sections of paper than necessary. Modern AEC software has tools to optimise the layouts, laying out information more compactly while still maintaining readability. This means the same content fits on fewer sheets or that smaller paper sizes can be used.

This approach is especially valuable for detail sheets and standard construction notes. Instead of printing each detail on a full D-size sheet and all the white space that entails, teams can arrange multiple related details together. The result is dramatically reduced paper consumption. The key is to keep appropriate scale relationships and ensure that text remains legible.

Printing Only Updated Sheets Instead of Full Sets

Printing revisions consumes a massive amount of paper when teams default to complete reissues. However, a typical revision doesn't need all sheets reprinted. If a revision involves changes to eight sheets within a sixty-sheet package, many firms are still stuck in the old ways of reprinting the entire package. Selective printing of revised sheets, which can be clearly marked with revision clouds, provides the same information with significantly less paper usage.

Complete reprints were common because tracking changes wasn't as easy as it is now. Modern document control practices track which sheets have changed, allowing partial reissues to integrate smoothly with existing printed sets.

How Smart Print Tools Reduce Waste Automatically

Technology has turned blueprint printing from a manual, error-prone process to an automated workflow that minimises blueprint waste with no effort. Modern print management software, such as that in the HP DesignJet series, creates a paper-saving print setup that reduces waste by:

- Analyses content

- Identifies optimisation opportunities

- Configures output settings

Nesting Features That Maximise Sheet Usage

Nesting algorithms automatically arrange multiple drawings on single sheets, eliminating the waste inherent to single-drawing-per-sheet approaches. These algorithms look at all of the documents that are batched together and calculate optimal arrangements that make the most of the usable area on each sheet. This can reduce paper usage by 40% or more.

Preview Tools That Catch Mistakes Before Printing

Modern print preview tools are much better at providing an accurate representation of what will appear in the final print. This functionality makes it easier to catch the type of costly errors that would require a reprint. These tools can catch and fix problems such as incorrect scaling, cut-off elements, misaligned content, or drawings sent to the wrong paper sizes before they waste paper. Modern printers can even flag some of these issues automatically.

How HP DesignJet Helps Control Costs and Reduce Waste

HP is a leader in print technology, packing the DesignJet series of plotters with paper-saving technologies built right into the hardware. With HP plotters, waste reduction is an automatic outcome rather than a manual effort. This makes it easier than ever to use paper-saving techniques when printing. The technologies include precise mechanical engineering combined with intelligent software to maximise the value of every print.

Accurate First-Time Prints That Avoid Reprints

The precision engineering of a DesignJet printer delivers consistent and accurate output that eliminates the need for reprints due to technical failures. Line weights are reliable, scaling is accurate, and colour reproduction is consistent, ensuring that each document prints correctly the first time. The reduced need for reprints also saves time and keeps projects on schedule.

Automated Optimisation for Frequent AEC Printing

HP's printing ecosystem is intelligent enough to understand the unique needs of several industries, including AEC. It understands what tender sets, construction documentation, coordination drawings, and site revisions are and is able to automatically apply a paper-saving print setup for each drawing type. This also ensures that print settings are consistent across all projects and team members.

Save Paper, Reduce Costs, and Maintain Blueprint Quality

Paper waste in AEC printing increases both the environmental and financial costs that firms incur. Technology has brought us to a point where the problems can no longer be ignored. But companies can easily solve these problems, and the firms that choose to do so gain a significant financial advantage. By using a modern plotter and adopting the above paper-saving techniques when printing, Malaysian AEC firms can dramatically reduce consumption while keeping the professional quality that commercial projects demand. To see for yourself, take advantage of the HP DesignJet promo today.

Explore plotter printers for your needs

HP DesignJet T850 36-in Multifunction Printer + HP Installation Service for DesignJet Series Entry Level (APJ)

A0 Color HP DesignJet Large Format Printer, Perfect for Business Print, copy, scan Dynamic security enabled printer 25 sec/page on A1 Ethernet, Wi-Fi Touchscreen, Automatic document feeder, Front USB flash drive port, Scan to PDF

MYR 18365.00MYR 17480.00Buy now

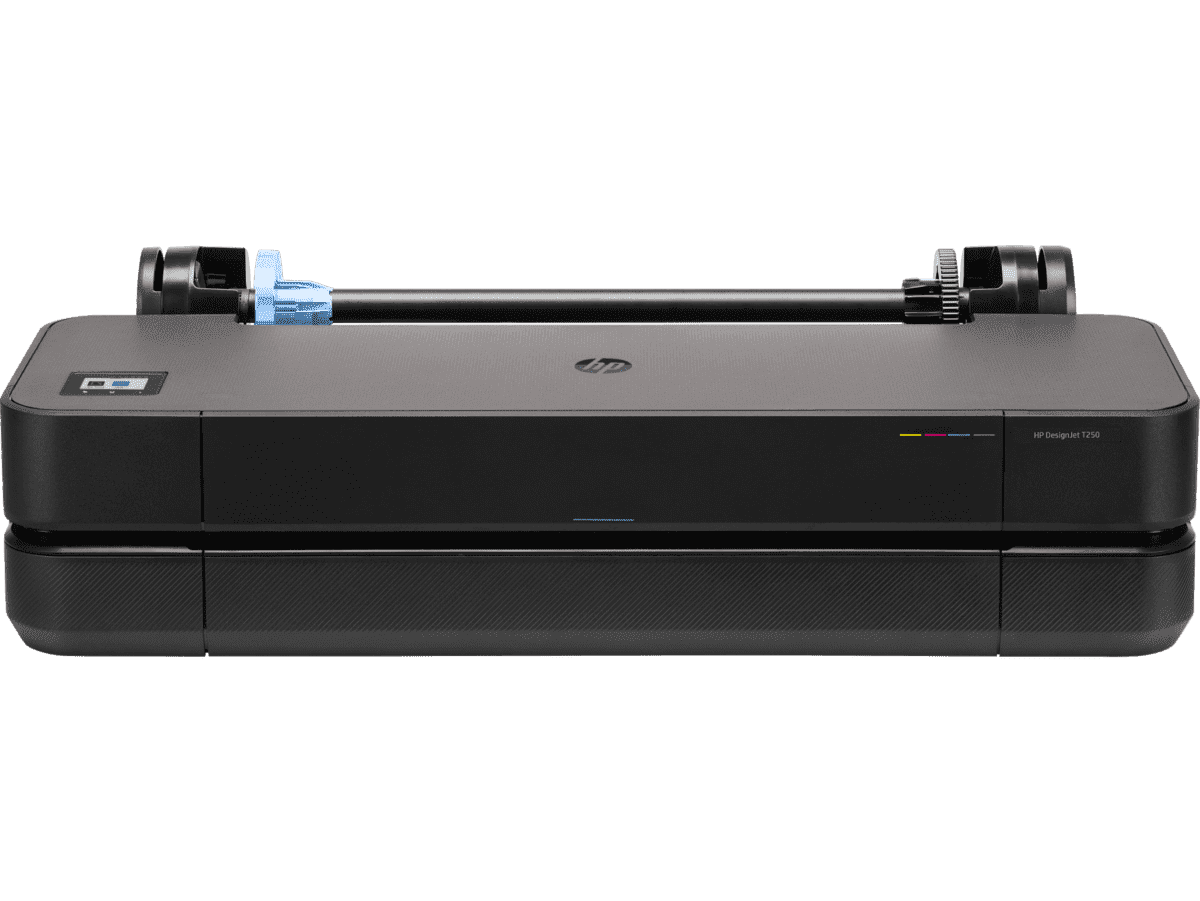

HP DesignJet T250 24-inch Compact Large Format A1 Plotter Printer + HP DesignJet T200/T600 Automatic Sheet Feeder + HP Installation Service for Design

A1 Colour HP DesignJet Large Format Printer, Perfect for Small Offices & Business Print 30 sec/page on A1; 76 A1 prints per hour USB, Ethernet, Wi-Fi Touchscreen; Automatic document feeder; Front USB flash drive port

MYR 5860.00MYR 4980.00Buy now

HP DesignJet T650 24-in Printer + HP Installation Service for DesignJet Series Entry Level (APJ)

Functions: PrintAuto sheet feeder: A4, A3; manual feed: A4, A3, A2, A1Print quality color: Up to 2400 x 1200 optimized dpiPrint speed: 26 sec/page on A1, 81 A1 prints per hour[1]Number of print cartridges: 4 (C, M, Y, K)

MYR 8570.00MYR 6880.00Buy now

HP DesignJet T650 36-in Printer + HP Installation Service for DesignJet Series Entry Level (APJ)

Functions: PrintAuto sheet feeder: A4, A3; manual feed: A4, A3, A2, A1, A0Print quality color: Up to 2400 x 1200 optimized dpiPrint speed: 25 sec/page on A1, 82 A1 prints per hour[1]Number of print cartridges: 4 (C, M, Y, K)

MYR 11640.00MYR 9880.00Buy now

You may also like

Plotter Printers

Plotter PrintersReducing High-Volume Printing Costs in Malaysian AEC

Plotter Printers

Plotter PrintersWhy using HP MFP for scanning helps reduce rework

- HP DesignJet

Cost-effective printing of safety plans and wayfinding information

- Plotter Printers

Plotter care habits that keep your blueprints job-ready

- How-To

How to nake your printer faster for urgent blueprints

- Digital Tools

Remote printing guide to increase AEC workflow efficiency

- Sustainability

How scheduling plotter saves electricity costs

- Plotter Printers

Cut AEC operating costs with HP Plotters

6 tips to portfolio printing for AEC professionals

- Digital Tools

How HP Click can streamline working processes

HP DesignJet

HP DesignJetBlueprint annotation guide: How to add notes that stay sharp on paper

GIS

GISPrinting topographical maps: What AEC professionals should know

How-To

How-ToA guide to large format printing for architects and designers

GIS

GISHow GIS mapping tools support large format printing for civil engineering

How-To

How-ToHow to use large format plotters for facility management floorplans

CAD Printing

CAD PrintingCommon print file types for blueprints explained

How-To

How-ToCommon mistakes and fixes for poor-quality blueprints

How-To

How-ToCommon printing mistakes: How to avoid costly errors in large format jobs

How-To

How-ToDigital vs paper: When to print architectural drawings and when to share digitally

How-To

How-ToBest practices for marking up and revising printed architectural plans